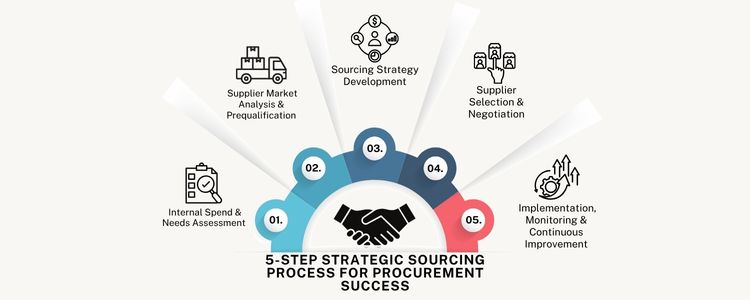

5 Step Strategic Sourcing Process for Procurement Success

Introduction: A Framework for Procurement Efficiency and Value

With today’s fast-changing international economy, with inflation, geopolitical volatility, and sustainability mandates straining supply chains, procurement is no longer just transactional. The function of procurement is the strategic enabler of value, resilience, and competitive advantage. To build enhanced value and resilience in meeting changing expectations, businesses must implement a reasonable, adaptable strategic sourcing process that aligns operational effectiveness with their business objectives.

This article describes a five-step framework that organisations—especially ones involved in sourcing from India or managing multi-regional supply networks—can use to standardise procurement activities and develop supplier relationships.

Step 1: Internal Spend and Needs Assessment

Every successful buying process has an agreed-upon intent: What is being bought, who is being bought from, and for what purpose? After agreeing to procure and deliver the item, an internal spend assessment will allow you to see more specific procurement categories and the degree of supplier concentration and spend patterns by various business units.

For example, a company that buys its raw material through a few vendors that are not consolidated under one agreement may suffer from inefficiencies caused by price variation, logistics exclusions (just in time procurement), and quality assurance. Proponents of good business have access to historical data and can forecast future demand. Analyzing the chargebacks and returns will build a consistent baseline for defining goals for savings, managing risk, and improving service levels (also intangibles) for the business enterprise.

Working through these issues can go a long way for product sourcing firms whoever they can be a long haul if you are an organization that accesses multiple geographies with numerous items in a multi-location based inventory. Real and relevant internal demand characteristics will ensure alignment of supplier capabilities in the next phases of the procurement process.

Step 2: Supplier Market Analysis and Prequalification

We can now assess the external supply landscape. Supplier’s market analysis finds suppliers and potential suppliers based off factors such as capabilities, capacities, location, lead times, certifications, and their approach to ESG.

Often, firms consider trade-offs between local sourcing versus global sourcing, and price on one side of trade-offs and potential for innovation.

For firms sourcing from India in particular, a higher degree of caution is warranted at this stage. India has a very interesting mix of cost advantage, skilled labour, and increasing technological sophistication. However, the due diligence process must also account for a significant amount of regional variability in both infrastructure and compliance standards.

A well-designed supply prequalification process narrows the options to a shortlist of firms that are commercially viable and operationally and ethically consistent with the firm’s values.

Step 3: Sourcing Strategy Development

With analyses for the internal and external environment complete, it will now be time to develop a sourcing strategy. In this process, the sourcing model will need to be determined, whether it follows a single-source, dual-source or multiple sourcing approach, as well as the period and type of relationship the supplier engagement will need to take.

The sourcing approach will be dependent upon your risk appetite, criticality of products, market volatility, and long-term strategic goals. For example, organisations that choose agility will often designate multiple regional suppliers, whereas organisations that choose cost-effective sourcing will consider high-performing companies as a central sourcing model.

During this phase, you should also develop any success measures, contract structures, and expectations of supplier performance, which will pave the way for clear and collaborative supplier relationships.

Step 4: Supplier Selection and Negotiation

Once the strategy is constructed, organizations issue RFPs (requests for proposals) or RFQs (requests for quotation) to short-listed suppliers. Evaluations should span beyond pricing to include delivery capacity, innovation performance, digital maturity, and after sales support.

Negotiation also should take a strategic tone—one that is designed to create shared value rather than short term cost benefits. At this stage, it is important to align with internal stakeholders to ensure procurement decisions align with business objectives, not just functional KPIs.

This step is particularly complex for global sourcing organizations that have to manage a large vendor network and adapt their negotiations in a way that takes into consideration regional variability. It is very real when suppliers in Europe have terms for payment and quality assurance protocols that are inherently different than suppliers from India.

Step 5: Implementation, Monitoring, and Continuous Improvement

The final step in the strategic sourcing process focuses on operationalising contracts and tracking performance. Implementation involves onboarding selected suppliers, defining communication protocols, and aligning logistics workflows. At this stage, digital tools—such as procurement dashboards and supplier scorecards—can help maintain transparency and accountability.

KPIs around quality, timeliness, responsiveness, and compliance must be closely monitored. Moreover, supplier relationships should be managed proactively through quarterly business reviews, innovation workshops, and issue-resolution protocols.

This step also includes ongoing supplier development, particularly relevant for suppliers in emerging markets. Organisations that invest in collaborative improvement efforts tend to build more resilient and adaptive supply chains—transforming vendors into strategic partners.

Conclusion: From Process to Performance

The last step in the strategic sourcing process focuses on making contracts operational and monitoring performance. The implementation includes onboarding suppliers, establishing communication protocols and deciding logistics workflows. At this stage, digital tools, such as supplier dashboards and scorecards, can help manage visibility and accountability.

Performance metrics around quality, timeliness, appropriateness, and compliance must be tracked closely. In addition, supplier relationships must be managed with the proactive scheduling of quarterly business reviews, innovation workshops, and issue resolution protocols.

This step will also entail ongoing supplier development, which is especially relevant for suppliers in developing and emerging markets. Organizations that invest in mutually beneficial development activities create more resilient and agile supply chains, which in effect transforms the vendor-seller relationship into a strategic partnership.