5 Ways AI Is Transforming the Global Sourcing Game

Introduction: A Shift in Procurement Intelligence

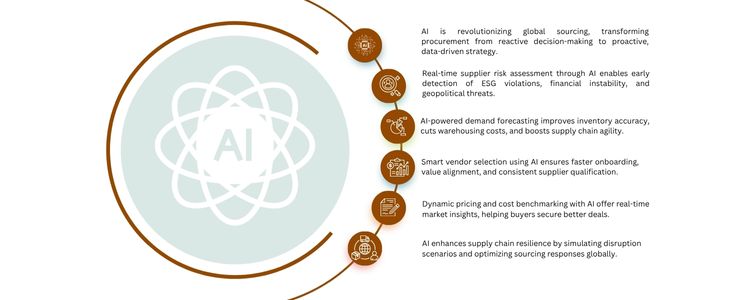

Historically, sourcing choices were largely reactive in nature; they tended to be based on supplier relations, price negotiations, and manual risk assessments. However, the sourcing landscape today is moving through a structural transformation and the increasing role played by AI in global sourcing is disrupting how businesses evaluate, oversee, and improve their procurement functions.

Artificial Intelligence, which used to be limited to niche applications, is now prevalent across key nodes of the sourcing value chain. AI is converting procurement from a manual assessment and reactive form to a data-driven, proactive function across several parts of the sourcing value chain ranging from evaluating suppliers and risk monitoring through price forecasting and demand planning continuous improvement.

Below are five key ways that AI is reshaping the playbook for global sourcing strategies.

1. Predictive Supplier Risk Assessment

Traditional risk assessment methods were typically based on static checklists and time-consuming processes to update the underlying data. However, now AI-driven platforms can comb through thousands of data points throughout news articles, compliance databases, weather reports, and social feeds, in order to identify risks with suppliers in real-time.

This gives procurement teams the ability to assess ongoing geopolitical disruptions, financial warnings, or ESG violations as they develop rather than after they have occurred, thus enabling the buyer to shift to alternate suppliers or re-negotiate supplier contracts based on their evolving risk profile.

These are extremely valuable capabilities for sourcing companies who source globally, often from hundreds of suppliers spread across multiple geographies and where visibility of supplier financial stability is an ongoing challenge.

2. Demand Forecasting and Inventory Optimisation

Forecasting was previously based on historical sales data and feeling. Today, more complex calculations through AI and machine learning are making demand forecasting more accurate. Many AI and machine learning algorithms factor in things like macroeconomic information, local events, consumer sentiment, and seasonality to predict demand for the future. Now supply chain teams can correctly order product in adequate quantities, better time their shipments, and avoid excess inventory or stock-outs. For firms with complicated global sourcing strategies, this means lower warehousing costs and more nimble supply chains; critical knowledge in an unstable business environment.

3. Smart Vendor Selection and Qualification

The selection of suppliers is no longer based only on overall cost and capacity. The sourcing leaders of today want partners that are aligned with their values, regulatory requirements, and quality expectations. Artificial intelligence tools allow today’s sourcing teams to much more quickly and effectively analyze sourcing data.

AI leverages a buyer’s historical supplier performance, supplier certifications, audits, and customer feedback to automate the qualification of suppliers. Some artificial intelligence tools allow for the ability to compare buyer requirements with supplier exceeds capabilities in an even more innovative way through Natural Language Processing. This saves buyers time, while improving buyer alignment with supplier capabilities.

Using artificial intelligence in the supply sourcing processes promotes faster onboarding and enables supplier evaluations to be applied equally and consistently across all suppliers.

4. Dynamic Pricing and Cost Benchmarking

One of the most significant advantages of AI relates to its ability to perform price discovery. AI systems can examine real-time pricing from different markets around the world to provide suggestions for purchase prices compared to the static RFQs, or other traditional benchmarking reports.

AI systems take the prices for raw materials, currency fluctuations, and freight fees and generate dynamic price models through the procurement process for key stakeholders. Companies can utilize this knowledge to negotiate terms, or time their orders.

Meanwhile, AI-enabled platforms are building transparency in industries where pricing has traditionally been opaque—giving buyers the opportunity to see better insight, and better deals.

5. Enhancing Resilience in the Global Supply Chain

Today’s supply chains have consistently proven fragile through numerous disruptions, be it through pandemics, trade disputes, or climate-induced failures. AI is helping to identify vulnerabilities and inform mitigation strategies.

AI models quickly allow simulations of all ranges of disruption effects on the supply chain and can assist businesses to build sourcing redundancy, reroute shipments of product, or switch to localised production when required. AI holds significant promise for companies in lean inventory models that may become vulnerable to scenarios of disruption.

As global supply chains become increasingly interconnected and at greater risk of exposure, AI is quickly emerging as an important tool to bring resilience and dampen the operational shocks of disruption.

Conclusion:

A Strategic Imperative, Not a Technology Experiment

For a long time in procurement, AI has been seen as experimental or future-oriented. Those times are behind us. Today, AI is not just changing the way companies source; it is transforming what the procurement function can do. Organizations that are thinking of AI as part of their global sourcing strategy are no longer considering “if” they will become high-performing organizations with AI as part of their core strategy, but rather, they are asking “how fast”? Agility, cost optimization, sustainability, responsible consumption, and risk management are just one of the key metrics that AI is beginning to affect in performance in sourcing.