Key Differences Between Quality Assurance and Quality Control in the Workplace

Quality assurance (QA) and quality control (QC) are powerful practices that guarantee the efficiency and reliability of any business offering. Although these terms are often used interchangeably, they are two distinct processes with different objectives and complementary goals. Every product introduced to the market must pass QA and QC and comply with certain quality standards, such as the FSSAI (for food items) and ISO series, to satisfy consumer demands and minimize environmental impact.

In a world where technology, services, and product development are always evolving, guaranteeing high-quality results becomes essential and the norm. Owing to this fact, most of the world’s valuable and recognizable companies have strict quality guidelines in place. For instance, Amazon requires its products to undergo functional, safety, and compliance testing to ensure a consistent customer experience. All of these are because 63% of customers prefer quality items rather than products that are of low grade. Therefore, if you are a business looking to launch a new product line or are interested in sourcing products, understand how QA differs from QC to be able to make informed choices.

Quality Assurance (QA)

Quality assurance is a subset of quality management that deals with bestowing confidence that the production process undergoes all systematic and planned steps to ensure the product and service satisfy the quality requirements. A structured and pre-planned approach protects against defects, and their attributes are achieved in reality too; that is what the product and service intended to do is done with consistency, accuracy, and efficiency. QA is done at different levels of the production procedure, including the processing level, organizational level, suppliers’ side, and final product stage. Further, it has two sides with different objectives: internal and external to attain. Internal is the management organization, and external includes customers, government, third parties, and other regulatory bodies.

Features of QA

- Process-Oriented: QA is concerned with defining, developing, and improving the processes that lead to the creation of a product or service, taking into account continuous technological advancements like AI and ML.

- Prepared: It identifies potential risks and issues early in the development process, aiming to fix them before they turn into defects. In short, it tackles the root cause directly early in the production process.

- Documentation and Standards: QA establishes guidelines, documentation, and protocols that the team follows to maintain required quality standards during the whole production process.

- Continuous Improvement: QA is designed to be an ongoing activity that evolves with the organization’s needs, often integrating feedback mechanisms to refine processes.

- Preventative Approach: QA uses training, guidelines, and regulated procedures to prevent mistakes instead of waiting for them to happen. It frequently conducts audits to verify adherence to established quality frameworks like Six Sigma and ISO 9001 and trains employees to do the same and eliminate quality gaps.

Quality Control (QC)

Quality control (QC) is a subset of quality management and quality assurance that deals with the inspection and testing of finished products to ensure they are safe and are fulfilling certain quality requirements. It is done to identify errors or defects and apply appropriate corrective techniques to fix them. Businesses strive for perfection, and quality is maintained and improved with required benchmark guidelines. Every industry has diverse techniques for measuring quality to make sure the final products are safe to use for customers to avoid any further legal issues. For instance, the agriculture industry must adhere to standards such as AGMARK, ISO 90001, and Goods Agriculture Products (GAP).

Features of QC

- Inspection: QC focuses on measuring and inspecting the final output against established quality standards. It looks for any violations of the established criteria, ensuring that the final product meets customer expectations. It may be carried out by regulatory bodies like the FDA or third-party inspectors.

- Testing: This includes various types, such as product testing, service testing, and performance testing, to verify that the final product works as intended and complies with pre-defined specifications.

- Sampling and Measuring: In certain industries, QC often involves taking samples from the production line or service outputs and performing tests to ensure that the finished product meets the required quality standards.

- Defect Detection: QC is nothing but identifying errors, flaws, or defects in the final product and ensuring they are corrected and safe to use before the product reaches consumers.

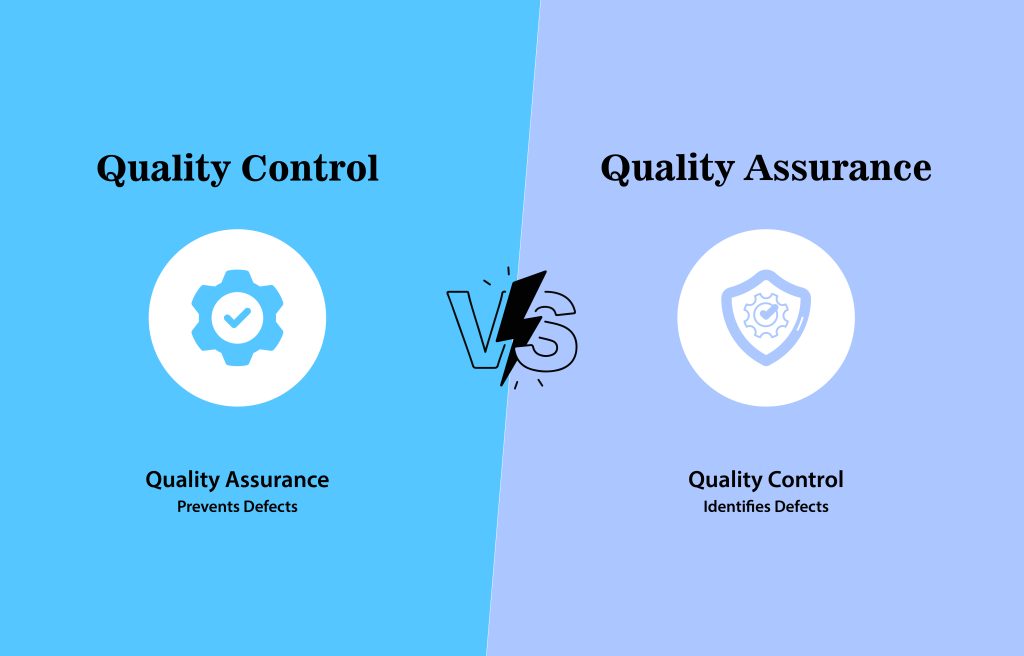

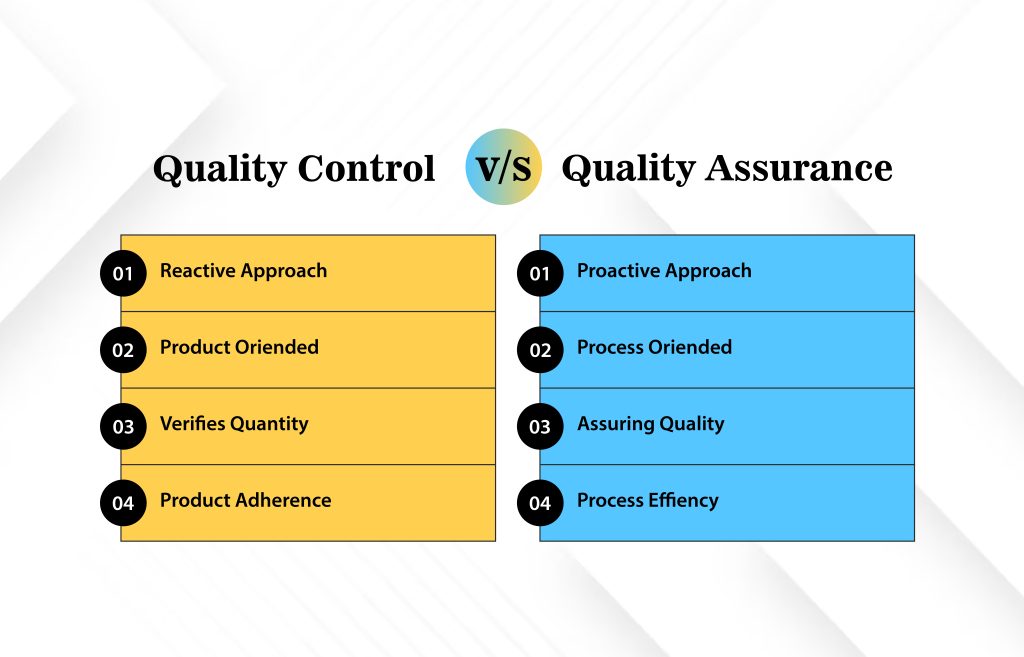

Key Differences

The two ideas have the same goal to attain, but the approaches are different.

Process

- The QA has a proactive approach that provides a framework to minimize the risks of defects or to eliminate them before occurring in the production process. It happens during the production process.

- The QC has a reactive approach as it conducts tests and inspections during the final stage of production to meet the standardized requirements. It happens after the final product has been produced to deliver the best quality to consumers.

Approach

- QA has a process-oriented approach as it focuses more on the improvement of processes, techniques, and production activities to provide the best quality products and tackle the defect from the root. It includes personnel training, documentation, and audits.

- QC has a product-oriented approach that eliminates defects in finished products with the help of various testing tools and regulations to meet the established standards. It includes batch testing, lab testing, and beta testing.

Focus

- QA focuses on assuring that the required quality standard will be achieved no matter how the changes have to be made in the process and techniques.

- QC focuses on fulfilling the quality as required by detecting errors in the final product and analyzing the things that need to be redone to match industry standards.

Techniques

- QA manages quality from start to finish of the production process. It maintains the same in every batch that is to be produced and activities that need to be integrated for that consistency.

- QC verifies quality after the whole process is done and undergoes several tests and inspections from various regulatory bodies to maintain the customer base with no discrepancies.

Measurement

- QA focuses on measuring the efficiency and effectiveness of processes, looking at how well processes are performing over time. If there is a need to change any of them, it will be done with training and upskilling the staff.

- QC focuses on measuring product adherence and checking the final output against quality standards. If the requirements change over time, it also changes the testing standards according to the standardized benchmarks.

Conclusion

In a nutshell, QA and QC are non-negotiable aspects of businesses striving for efficiency and precision. The next generation of QA will be highly focused on speed and accuracy catering to the growing demands of real-time data and feedback. It will be made possible by innovations like data analytics, AI, and ML that are already transforming quality control operations with high-end predictability, automation, and error analysis. These trends will further shape the quality management landscape in 2025 and beyond by significantly lowering manual efforts and improving test coverage. Products will seamlessly tick off complex quality standards without hiccups, and ultimately businesses will be able to stick to their quality and sustainability goals.