5 Vendor Sourcing Mistakes That Are Killing Your Supply Chain

In today’s unstable global market, vendor sourcing does not mean just purchasing; it is also to create flexible supply chains. By 2030, global trade is expected to cross the 8 trillion dollar mark through outsourcing, in which India will be established as a global sourcing partner due to its 14% lower manufacturing costs, giant supplier ecosystems, and government-run free trade agreements (FTA). Whether you are sourcing apparel, shoes, electronics, or packaged goods, India’s cost-efficient and digital infrastructure makes it a favourite global sourcing partner.

But even in this development environment, a weak sourcing decision can begin a series of disruptions. As a leading sourcing agent in India, at Inductus Global, we have identified 5 such mistakes of vendor sourcing that silently damage your supply chain and profitability.

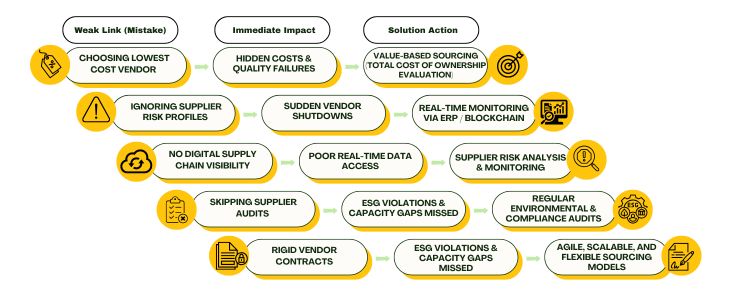

The Chain Reaction Model: How Mistakes Break Supply Chains

| Weak Link (Mistake) | Immediate Impact | Downstream Disruption | Solution Strategy |

|---|---|---|---|

| Chasing the Lowest Cost | Hidden costs and compromised quality | Project delays, rework cycles, and customer dissatisfaction | Prioritize Total Cost of Ownership (TCO) over initial price |

| Ignoring Supplier Risk | Exposure to supplier failure | Production halts and inventory stockouts | Implement continuous supplier risk assessment |

| Lack of Digital Visibility | No access to real-time procurement data | Inventory imbalances and unplanned operational costs | Adopt digital sourcing tools like ERP and blockchain |

| Skipping Ethical & Capability Audits | Non-compliance with ESG standards | Reputational damage and legal exposure | Conduct second-tier audits and score supplier capabilities |

| Overreliance on Rigid Long-Term Contracts | Limited sourcing flexibility | Inability to scale or pivot quickly | Use flexible, performance-linked sourcing agreements |

1. Running Behind the Cheapest Seller.

Cheapest is still being regarded as the best by the many businesses. However, when sellers are selected only based on how low their quotation is, it often results in low-quality products, refunctioning, and hidden expenses in logistics. In the survey, 61 percent of the business-related research showed unplanned sourcing costs because of disregarding the hidden costs.

Solution:

Adopt the total cost of ownership (TCO) method to ownership; it is not just about the price, but the lead time, the quality standards, and logistics in addition to the after-sales risks.

2. Ignoring the Financial and Operational Risks of the Supplier

Working with a single-source or financially unstable vendor can stymie your entire supply chain overnight. More than 45% of companies faced supplier failure during 2023 due to unexpected risks.

Solution:

Use continuous supplier risk assessment models covering financial health, geopolitical risks, and ESG performance.

3. Lack of Digital Supply Chain Visibility

In 2025, supply chains will require digital control. Manual sourcing procedures cause delays, deadline omission, and high logistics costs. Companies with sourcing visibility in real time reduce disruption by 32%.

Solution:

Apply ERP, blockchain, and AI-managed supplier platforms to monitor compliance in various stages of production, shipment, and sourcing.

4. Ethical, Environmental, and Audit Avoidance

The brands now demand moral, durable, and traceable products. Without a proper supplier audit, you risk compliance failures and brand damage. More than 71% of global retailers now prioritise source partners with clear ESG certification.

Solution:

Audit the second-level supplier to ensure stability and capacity beyond paperwork.

5. Rigid Sourcing Contract

The post-pandemic market is dynamic. Hard, long-term vendors without flexibility are bound by contracts; your ability to increase or change the sellers when needed is limited.

Solution:

Scalability and interaction on agile, performance-based agreements enable scalability and alternative sourcing routes.

Why Choose India as Your Global Sourcing Partner?

With its 1 trillion US dollar export target for 2030, India is rapidly emerging as the world’s product sourcing center, especially in the fields of apparel sourcing, footwear sourcing, and electronics. Major benefits include

- 14% lower production cost compared to China (Source: World Bank)

- Over 45,000 MSME manufacturers in major areas

- Government-backed initiatives such as PLI schemes and FTA-operated fee exemptions

- Ensures fast digitisation, real-time tracking, and transparency

Conclusions

Seller sourcing is not a transaction step—it is a strategic pillar of your supply chain success. By identifying these five weak links and fixing them, companies can create flexible, reactive, and future-supplied supply chains.

Inductus Global, as your reliable sourcing agent in India, helps businesses to convert their seller sourcing into a competitive advantage from the cost center – in custody, in ability, in footwear sourcing, and in broad global sourcing requirements.