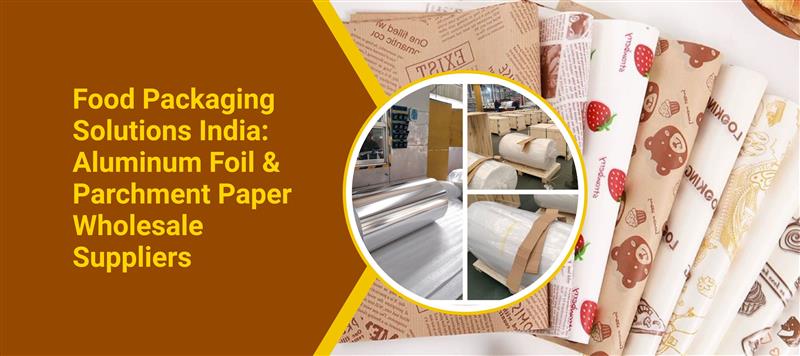

Food Packaging Solutions India: Aluminum Foil & Parchment Paper Wholesale Suppliers

Over the last 10 years, India’s food packaging industry has been changing because more people know about food and also because food services are growing quickly. Because there are more people looking for food service products, more customers want to buy food packaging products from the country. Global customers now want Indian food packaging products to be reliable, affordable and good quality. The main types of food packaging products that consumers want are aluminium foil and parchment paper.

Foil and parchment paper are two of the most important types of food packaging materials and help keep food fresh, increase shelf-life of food, and comply with international food safety regulations. Because of its strong manufacturing base, strong compliance framework, and growing number of export-oriented companies, India is an ideal country for companies to source large quantities of food packaging products. Companies that sell food products, bakeries, food processing, retail stores, and wholesale suppliers can use India to find high quality, cost-effective food packaging products that can be purchased in large quantities.

1. The Growing Importance of Food Packaging in a Changing Market

Food packaging has become increasingly important as a product’s package represents a fundamental quality assurance system, as well as hygienic food safety, and adds value to a company’s brand. With the current trends of changing global food consumption patterns, there is a simultaneous increase in the requirement for dependable food packaging materials.

The Indian Packaging Industry is experiencing rapid growth due to:

- Rapid Developments in Ready-To-Eat and Ready-To-Cook Categories

- Increasing Global Demand for Safety and Hygiene in Food Packaging Materials

- Increases In Food Exports And the Presence Of Private Label Products.

- Technological Innovations In Packaging Machinery

The above trends are providing increased credibility to Food Packaging Paper Suppliers and Foil Manufacturers in the Global Supply Chain.

2. Why Global Buyers Choose India for Packaging Materials

India is a preferred source of Aluminum Foil or Parchment Paper due to several factors.

- Pricing & Reliable Supply

India has a large manufacturing base, which allows exporters to provide larger loads of aluminum foil and parchment paper (wholesale food packaging prices) at very competitive prices on a consistent basis. This is important for businesses that are placing large/repeat orders.

- Compliance & Certification

Leading Indian manufacturers are compliant with many international standards, including ISO and BRC, and the FDA accepts their products. This means that the packaging materials will be safe for use in direct contact with food and that all safety requirements are met.

- Highly Developed Technology & Skilled Work Force

India has invested heavily in modern manufacturing technologies, including fully automated rolling mills, precision cutting units, and high-speed coating machines, to ensure that the products manufactured in India will be consistent and durable, with exact sizing.

- Custom Thickness and Private Label Options

Companies in India often offer custom thicknesses, custom roll sizes, branded rolls, and a variety of packaging options for private label programs.

3. Aluminium Foil : A Cornerstone of India’s Packaging Sector

Aluminium foil is currently the most popular food packaging material globally, as it protects food from moisture, air and contaminants. As a result, Indian manufacturers are major suppliers to the world for both cooking-grade aluminum foil and for industrial-grade foils.

What Indian Suppliers Provide:

- Variety of Thicknesses for Food Use (9 to 18 Microns)

- Anti-Grease, Heat Resistant, and Food Safe Options

- Available as Bulk Rolls for Commercial Kitchens and Food Processors

- Packaged for Easy Retail Sale for Supermarkets

Companies Listed As “Aluminium Foil Manufacturers” That Export Meet International Standards and Have Consistent Tensile Strength, Thickness, Surface Finish, and Logistics Operations with Economies of Scale.

4. Parchment Paper : Expanding Demand Among Bakeries & Food Processors

The increase in global demand for parchment paper has resulted from the change in baking and food processing towards healthier and chemical-free packaging. Parchment paper makers in India see a growing number of high-quality parchment paper exporters as a result.

Parchment Paper Made in India Features:

- Silicone Coated, Heat Resistant Sheets Designed for the Oven

- Moisture Resistant and Grease Resistant

- Food Safe Non-stick Surfaces for Baking and Wrapping

- Eco-friendly Options That Support Global Sustainability Initiatives

Characteristics of parchment paper contribute to its use in confectioneries, chain bakeries and the industrial food production sector.

5. Understanding Food Packaging Solutions India : What Buyers Should Expect

When purchasing packaging materials from Indian suppliers, buyers typically seek reliability, compliance and flexibility. Leading suppliers of Food Packaging Solutions India offer:

- Complete Production Capabilities, Including Rolling, Coating, Slitting, and Packing

- Consistent Quality Control Procedures, With Batch Testing of Thickness, Porosity, and Strength

- Flexible Procurement Models For Both Bulk Buyers and Private Label Clients

- Sustainable Alternatives Including Recyclable, Biodegradable and Paper Substrates

This ecosystem exists to provide global importers with on-time, high-volume and certified Packaging Solutions.

6. Role of Food Packaging Paper Suppliers in Supply Chain Efficiency

The need for reliable food packaging paper suppliers goes beyond just product availability; exporters also offer significant value through:

- Inventory Planning and Stock Control

- Timely Shipment Based On Seasonal Requirements

- Custom Packaging Formats Available To Industrial And Retail Customers

- Strict Compliance With Food Safe Material Handling Procedures

Having An In-Depth Knowledge Of The Numerous Different Global Markets Provide Increases In Procurement, Predictability & Reduces Vulnerability In The Supply Chain.

7. Packaging Foil Suppliers : What Sets Indian Manufacturers Apart

Due to India’s capabilities in the manufacturing of metals, its aluminium foil exports have increased significantly. Leading suppliers of packaging foils have several competitive advantages, including:

The ability to produce packaging foils quickly and at a consistent cost (high volumes).

Rigid quality control measures.

The ability to furnish customers with both large rolls (industrial reels) and smaller roll sizes (consumer grade).

Cost-effective shipping on Export (by) shipping from the main Ports.

In addition to the competitive prices that Indian foil suppliers provide to buyers interested in long-term relationships with their suppliers, there is a highly developed supply chain that provides these buyers with a reliable source of materials to manufacture their product.

8. Factors Influencing Wholesale Prices and Procurement Decisions

Several factors exist concerning pricing when determining the cost of packaging foils from India. These include:

- Changes in global aluminium prices.

- Changes in the price for raw paper and pulp.

- Changes in the cost of freight and availability of containers.

- The impact of changes in export policies or regulations.

- Seasonality of demand in the food industry.

Tracking the prices of Wholesale Food Packaging in India can help retailers, distributors and food manufacturers determine when to make bulk purchases.

9. How to Assess and Shortlist Reliable Suppliers

Importers should evaluate suppliers based on:

- Certifications (ISO, FDA, BRC, SGS)

- Production capacity and machinery standards

- Track record in export markets

- Testing and quality assurance processes

- Ability to support custom orders

- Efficient communication and after-sales service

Sampling products before finalising long-term contracts is a widely adopted best practice.

Conclusion

Today, India has a growing expertise in manufacturing aluminum foil and parchment paper, making it a global technology and innovation leader in manufacturing high-quality, low-cost packaging products. As the demands of the global food service, retail, and export markets continue to change, the use of Food Packaging Solutions from India will become increasingly relevant for companies that want reliability, compliance and the best value. With highly advanced manufacturing techniques and knowledgeable food packaging paper manufacturers, India is uniquely qualified to support the packaging needs of customers around the world in all industries.