Why Russian Industries Are Looking to India For Chemical Supplies

International trade structure for chemicals has changed dramatically in the last several years. The changing political environment due to geopolitical tensions, financial constraints, and logistical disruptions has led to new sourcing strategies across various industries. Manufacturers in Russia are currently reviewing their historical supply chains and are looking for alternatives that provide them with stability, scalability and long-term reliability. A growing number of these manufacturers are now partnering with bulk chemical suppliers who are based in India.

This transition is a strategic recalibration and is reflective of the deep changes in Russian industries’ perception of risk, resiliency and value within the global chemical ecosystem.

Changing Priorities in Russian Industrial Procurement

The Russian industries across all types – from fertilizer and petrochemical to pharmaceutical and consumer goods – are reliant upon chemical feedstock. In the past, a significant portion of the chemical feedstock demand from Russian industries was fulfilled by chemical suppliers located in Europe and through integrated regional supply chains. Recent disruptions to supply, however, have exposed weaknesses in these supply arrangements.

Procurement strategies for these industries are being redefined based upon continuity of supply, pricing predictability and political neutrality. As a result, India is quickly becoming a credible and desirable partner for chemical manufacturers in Russia by offering both depth of production and strategic flexibility.

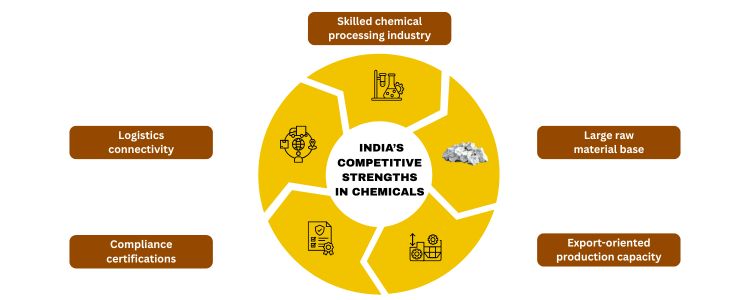

India’s Expanding Role in Chemical Manufacturing

During the past twenty years, the chemical sector of India has continued to expand, beyond just being a producer of basic products (commodities), and now includes the production of specialty and performance chemicals as well. This is due, in part, to industrial clustering, skilled technical labour, and government policies supporting high levels of export-driven production from India. The capabilities of Indian chemical manufacturers to supply very large quantities of material, at a constant level of specification, have provided Russian buyers with assurance that they will have both capacity and technical capability.

The existence of established chemical manufacturers in India creates a level of comfort for Russian buyers that they will receive material from a reliable source with a well-established track record.

Indian chemical manufacturers supply chemical materials used to produce a wide variety of products, including inorganic chemicals, intermediates, polymers, and additives. All of which are critical components to the overall industrial production of Russia.

Cost Competitiveness and Pricing Stability

One of the major reasons that Russian buyers have a strong interest in acquiring chemicals from India is due to the cost structure. Because of the lower operating costs, which are attributable to the availability of domestic raw materials, and economies of scale in large production facilities, Indian chemical manufacturers are able to provide chemicals to the market at competitive prices while still maintaining a reasonable level of quality.

The current economic environment is characterized by currency fluctuations and changes in transport costs; therefore, pricing stability is a major concern for many purchasers. Most Indian suppliers provide longer-term contracts with more clearly defined pricing structures, thereby allowing Russian manufacturers to plan their production activities with more confidence.

Supply Reliability Amid Global Disruptions

In the last few years, it has become clear just how fragile the global chemical supply chain is. The traditional movement of chemicals has been interrupted by the impact of sanctions, port congestion and energy price increases. As a result, Russian chemical-producing companies are now focused on establishing relationships with those suppliers who can provide larger amounts of flexible logistical capabilities for shipping.

Through its location and multiple maritime corridors, India provides flexibility to Russian importers looking for reliable sources of chemical products. The experience of Indian exporters servicing markets throughout Asia, Africa and South America has provided them with an established operational experience relative to the complexities involved in a changing global market place. As a result, they have been increasingly positioned as the preferred suppliers due to their adaptability.

Regulatory Compatibility and Technical Standards

The importation of chemicals is one of the most closely regulated applications within the industrial chemical sector, primarily due to how these products are used for pharmaceutical applications, food manufacturing, and advanced manufacturing. Indian exporters have already experienced large amounts of capital investments in the form of facilities and processes that convert into compliance infrastructures. For example, they have established quality control laboratories, certification systems, and documentation that is consistent with the established international norms.

The investment by Indian exporters in these infrastructures reduces the Russian importer’s burden to demonstrate compliance and streamlines the process for customs clearance. Suppliers that can prove their adherence to accepted safety and environmental standards are becoming more important as suppliers of large amounts of industrial chemicals.

Industrial Demand and Sectoral Drivers

The demand for imported chemicals in Russia spans multiple sectors. Fertiliser production requires steady inputs of intermediates and additives, while construction materials depend on resins, coatings, and specialty compounds. Consumer goods manufacturing, meanwhile, relies on a range of solvents, surfactants, and polymers.

Within this context, partnerships with industrial chemicals suppliers in India offer Russian firms access to a broad portfolio from a single origin. This consolidation simplifies procurement and reduces dependency on fragmented sourcing networks.

Logistics, Trade Routes, and Payment Structures

Beyond production capacity, trade mechanics play a critical role. India’s ports and shipping infrastructure have demonstrated resilience, even during periods of global disruption. Regular shipping schedules and established freight corridors have enabled Indian exporters to maintain delivery timelines.

Equally important are evolving payment arrangements. Russian and Indian firms have explored alternative settlement mechanisms, reducing exposure to financial bottlenecks. These practical adaptations have reinforced mutual confidence and encouraged deeper trade engagement.

Strategic Alignment and Long-Term Outlook

There are various industries that require imported chemicals in Russia; these industries are Fertiliser Manufacturing with regards to intermediates and additives, Building Materials (Construction Materials), which depend on resins, coatings and specialty compounds, and Consumer Products Manufacturing, which utilises a variety of solvents, surfactants and polymers.

Industrial Chemical Suppliers in India (Supplier) provide a number of potential partnership opportunities that offer access to a large range (Portfolio) of Products with only one point of Contact (Source) for Russian Companies; consolidation of this Supply Base (Source) will create less complexity in procuring, as well as reducing dependency upon fragmented Sourcing Network(s).

Challenges and Risk Considerations

Trade Mechanics also contribute to the Producer-GDP, along with Production Capacity. As evidenced with both Producers and Exporters of India, both of whom have demonstrated a good degree of resiliency (throughout Global Disruption), Regularity of Shipping and Shipping Corridors have also played a major role in maintaining delivery schedules by Indian Exporters.

Additionally, evolving Payment Terms between Russian & Indian Companies have enabled further exploration of Alternative Payment methods, Significantly reducing exposure to bottlenecks in Financial Reporting. Such Practical Solutions, as well as creating Greater Level(s) of Confidence between both Companies, will likely create Further Engagement between the two Partners regarding Future Trade.

India’s Position in the Global Chemicals Landscape

The growth of India as a supplier of industrial chemicals is a reflection of the larger changes taking place in the global chemicals marketplace. As consumers shift to purchasing products from emerging markets and new sourcing centres, India’s size, technological ability, and readiness to export put it at the forefront of this transition.

For Russia, developing relationships with Indian suppliers is not simply about finding someone to fulfil your current supply needs; it also represents an investment in building a more resilient and flexible supply chain for the future.

Conclusion

The increasing presence of Indian chemical suppliers in the Russian market is indicative of a changing landscape for both countries in response to shifts in global trade patterns. Cost-effectiveness, dependable supply, and readiness for compliance with regulations have made India a highly competitive and appealing country from which to source chemicals.

Going forward, as trade continues to evolve, new partnerships that promote mutual benefit and clarity in operations will develop. Therefore, the use of Indian chemical suppliers as a source by Russian manufacturers represents a straightforward, effective, and practical means to secure long-term success in a time of global uncertainty and volatility.

Frequently Asked Questions (FAQ)

They value India’s consistent quality, diversified logistics, and growing export reliability.

India exports both Arabica and Robusta, catering to premium and commercial segments.

Yes, particularly green beans that allow roasters to control flavour profiles locally.

While distances are longer, experienced exporters manage transit effectively through established routes.

Yes, driven by diversification strategies and steady growth in Russian coffee consumption.